When Cold Meets Heat: The World of Temperature Shock Chambers

Ever consider who scientists and engineers figure whether materials can bear extremely low temperatures or extremely high temperatures? Check out the temperature shock chamber. It’s this innovative technology that makes materials deal with extremely rapid and dramatic temperature fluctuations. These facilities are crucial in numerous industries, like aviation and automotive. They guarantee that products can endure the harshest conditions.

Temperature Variability

Temperature changes are very significant when evaluating materials in such shock chambers. These facilities can go from extremely cold to extremely hot quickly.

It’s like the enclosures are reproducing what happens in the physical world, like aircraft in the atmosphere or devices in extremely hot or extremely cold locations. For instance, according to a study published by the NIST (NIST), temperature shock test can reveal vulnerabilities in substances that might not be detectable under standard conditions.

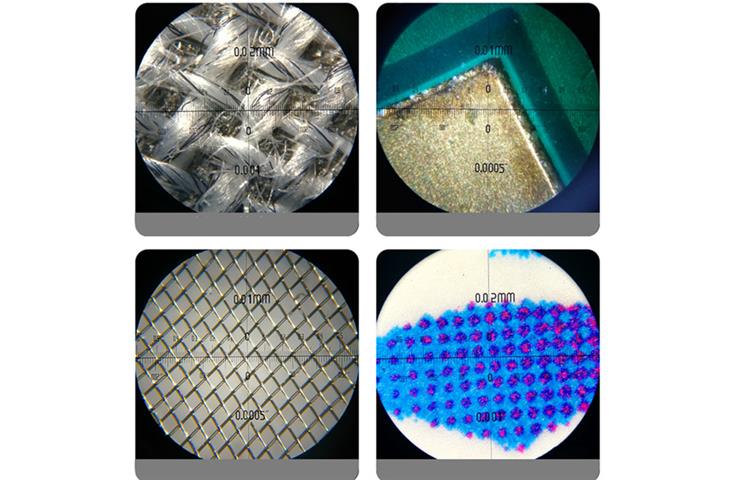

Material Testing

Material testing is extremely important when using these shock enclosures. The enclosures help check how substances handle really cold or hot temperature ranges, making sure they’re trustworthy and last durable.

Take the space industry, for example. They use this testing to ensure parts can handle extremely cold temps up elevations and the heat when they come back down. American Society for Testing and Materials says this testing is essential for maintaining the state of secure and operating efficiently.

Environmental Simulation

These enclosures can also copy a broad spectrum of various environmental conditions. These enclosures can mimic a wide range of environmental conditions, from severe cold to high heat, and even humidity conditions.

This is really helpful in the automotive industry, where cars need to be tested in different climates. GFZ Institute did a study showing how These enclosures can accurately copy real life conditions, giving useful information for automobile design.

Quality Control

Quality Assurance is super important in manufacturing products, and These enclosures help make sure the products are good. Manufacturers can spot possible issues before they become actual issues by testing materials and products in extremely high temperatures. International Organization for Standardization says this testing is a big part of making sure Quality Assurance works well in many industries, and it helps prevent costly catastrophes and product recalls.