The Ultimate Guide to Thermocouple Welder Machines

The principle of Thermoelectric technology is utilized by a efficient device called a thermoelectric welder, to join metals with accuracy.information of thermoelectric welders, their operation principles, and the various benefits they offer in the domain of metal welding are explored in this article.

thermoelectric welders comprise:1. Thermocouple Elements: These are the basic elements, producing an electromotive force in direct proportion to the heat variation between two different metals.2. Control Module: The welding operation is regulated by the Control Module, which surveys and modifies the heat.3. Power Source: The required electrical power for the welding operation is provided by the Power Source.

4. welding gun: The heat is transmitted to the metal substrates for fused through the device referred to as the welding gun.thermoelectric welders are used for:1. Industrial Welding: The manufacturing sector widely employs thermoelectric welders for welding metals across multiple uses, such as vehicle manufacturing, aviation and space, and building.

2. Repair and Servicing: These machines are suitable for repairing damaged metal parts, such as equipment and machinery, by providing accurate and managed welding.3. investigation and innovation: Thermocouple welding devices are vital in investigation and innovation, enabling researchers and engineers to experiment with new materials and techniques.

4. Hobby and DIY Projects: enthusiasts and do-it-yourselfers can use thermocouple welding devices to create bespoke metallic objects and carry out fixing metallic objects.The benefits of thermocouple welding devices include:1. High Precision: Offered by thermocouple welding devices is precise control over the welding process, which results in high-grade weldments with least deformation.

2. energy-saving: Consuming less energy than traditional welding methods, these machines are more ecologically beneficial and economical.3. Safety: Ensuring a secure working atmosphere, the regulated process of thermocouple welding minimizes the likelihood of incidents and injuries.4. Versatility: A versatile equipment for different applications, thermocouple welding devices can be used for several metal welding procedures.

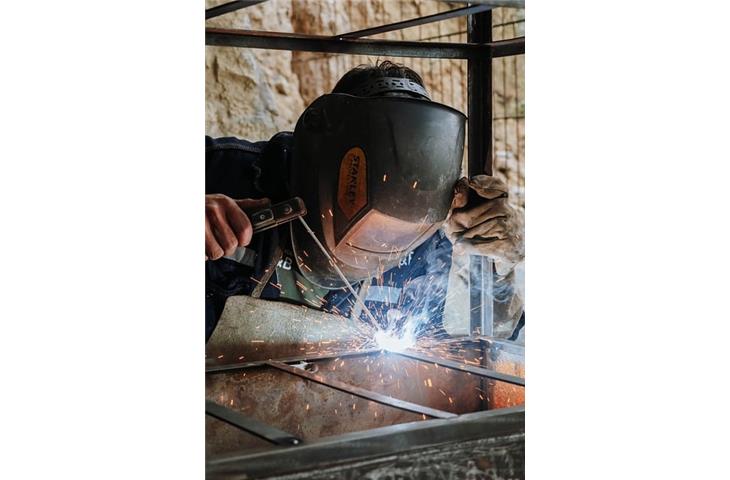

When operating a thermocouple welder, safety considerations include:1. Proper Training: To ensure the safe and efficient operation of the thermocouple welder machine, operators need to be trained correctly.2. Protective Gear: To protect against dangers, workers should wear correct safety equipment, such as eye protection, hand protection, and safety attire.

3. environmental protection measures: to reduce exposure to smoke and fumes produced during the welding procedure, adequate ventilation should be ensured.4. frequent maintenance: Preventing accidents and ensuring best performance, frequent maintenance of the machine is essential.Maintaining and troubleshooting a thermocouple welder machine involve:

1. Regular Inspection: Identify any signs of deterioration, loose connections, or defective parts through periodic checks.2. Cleaning and Lubrication: Maintain efficient operation by cleaning the equipment parts and adding lubricant as required.3. Calibration: Ensure correct temperature measurements and steady welding results by adjusting the control module and thermocouple sensors periodically.

4. Problem Solving: Resolve any issues that can occur during use swiftly by gaining familiarity with usual problems and their Problem Solving steps.Many advantages in terms of accuracy, efficiency, safety precautions, and flexibility have been provided by the thermocouple welding units, revolutionizing the welding sector.

When selecting the right thermocouple welder for their needs, people along with companies are able to make well-informed choices by being aware of the parts, uses, and advantages of these machines.Offering dependable and premium welding services for a wide range of uses, thermocouple welding units can, with adequate training, safety precautions measures, and upkeep, be properly utilized.