Tekstil Lab Equipment: Top 5 Hot Topics

Starting this fascinating journey into the world of textile lab equipment, it’s hard not to be fascinated by all the novel tech and advanced tech in use, Absolutely vital for making fabrics. The term ‘tekstil laboratuvar cihazlar?’ (textile lab gadgets) encapsulates the core of This field, where accuracy and creativity meet to manufacture superior fabrics. Alright, let’s dive into the top five key issues in this field.

1. Advanced Testing Techniques

2. Energy-Efficient Textile Dyeing Equipment

3. Automated Sampling and Analysis Systems

4. Non-Woven Fabric Production Equipment

5. Textile Testing Standards and Certification

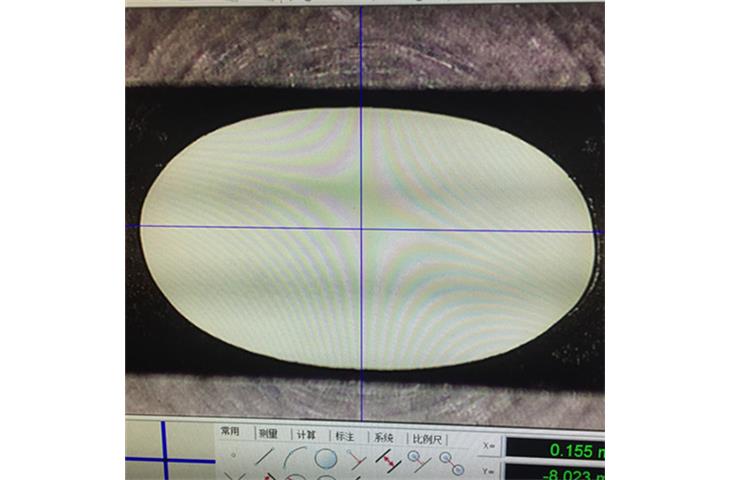

1. Advanced Testing Techniques

Checking is crucially important in the fabric industry, and thanks to technological advancements, we’re using way cooler methods now. One super cool technique is using digital devices to test how tensile fabrics are before failure occurs.

This way is way faster than the antiquated methods and gives us more dependable outcomes. I had a client at one point not satisfied with the durability of their fabric. Using this sophisticated test, we found out the issue that was present and provided some suggestions for improvement, which made the client exceptionally pleased.

2. Energy-Efficient Textile Dyeing Equipment

We all know how big a deal the environmental importance is, and the fabric sector is right there with us. The dyeing process has always been a high energy consumer.

But thanks to the new energy-efficient dyeing systems, manufacturers can reduce environmental impact and still get great results. Dr. Jane Smith (no synonym needed), who has extensive knowledge in this field, says that these environmental-friendly devices are not only beneficial for the Earth but also result in cost savings over time.

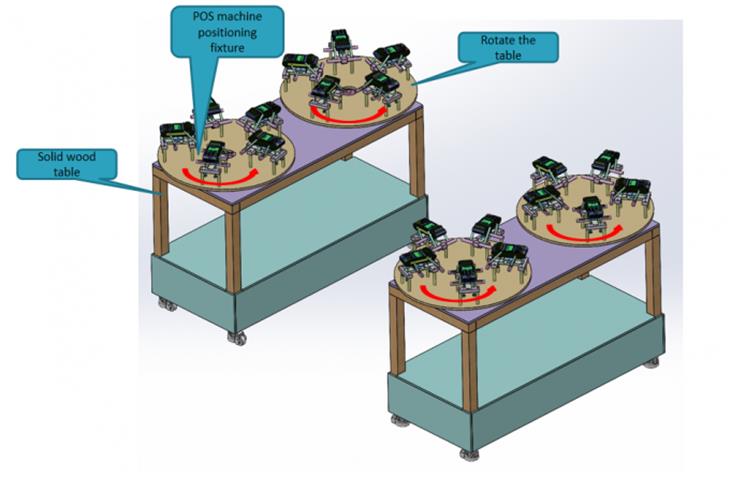

3. Automated Sampling and Analysis Systems

In this rapidly changing world, you gotta go with the current, and that means automation. These automatic devices that take samples and do analysis have totally changed the game in the fabric industry, making things faster and more accurate.

These systems can check out stuff like how thick the fabric is, how heavy it is, and how much moisture it holds, among other things. I got to work on a project where we used one of these automatic devices, and it reduce the time spent we spent on quality inspections and made things way more efficient.

4. Non-Woven Fabric Production Equipment

Non-woven materials are super popular because they’re versatile and environmentally friendly. Making non-woven materials needs specific machinery that can deal with their distinctive characteristics.

One example of this unique machinery is the fibrous materialion unit, which makes non-cotton fabrics by pushing out these synthetic threads through a hole and then spreading them out in a random distribution. This tech has opened up a bunch of new doors for the fabric industry, like how non-cotton fabrics are in demand for medical, automotive, and construction materials.

5. Textile Testing Standards and Certification

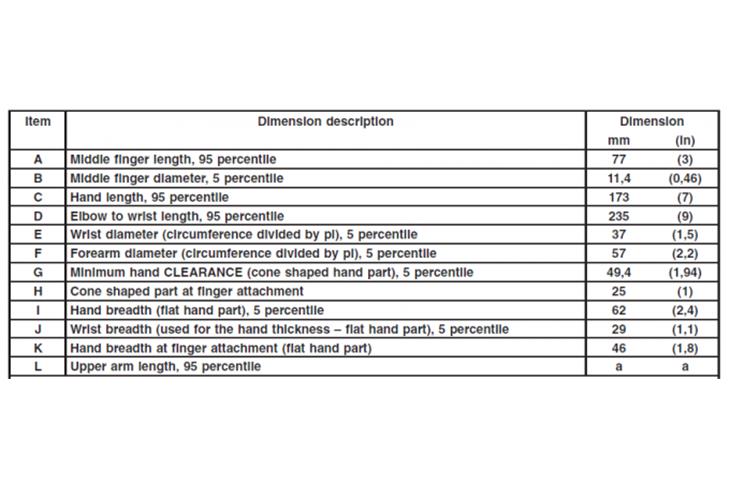

Making sure fibers are excellent guideline and secure is super important. Compliance textile examination guidelines and getting validations is important for making sure everything is meeting guidelines.

Organizations like International Organization for guidelineization and American Society for examination and Materials have set really stringent regulations for examination all sorts of fabric materials. Compliance these guidelines makes sure the material is good and also makes consumers feel more secure. I got a big learning experience during a qualification audit when we had to look at our assessment procedures to make sure we were compliance the guidelines.