Sale of Meltblown Fabric Machines: The Ultimate Guide

The fabrication device the environment is very active, always developing innovative concepts for various uses. These devices totally transformed the way fabricated nonwovens are made. They’re super crucial in things like face masks and protective equipment. We will explore thoroughly everything about these devices, from operation mechanism and all the benefits their functions.

2. Meltblown Filter Nonwoven Fabric Machine

3. Advantages of Meltblown Filter Nonwoven Fabric Machines

4. Safety and Environmental Considerations

1. Meltblown Nonwoven Fabric

Meltblown Nonwoven Material is a type of synthetic fiber material made by forcing heated material through a small aperture and then extending it in a special way. This process creates a fibrous arrangement with superior filtration characteristics.

The fabric that comes out of it is really easy to breathe through, comfortable against the skin, and has a long lifespan. This fabric is a major factor in producing face masks. It gives the required defense from microscopic particles in the air.

2. Meltblown Filter Nonwoven Fabric Machine

This machine is like the key device when it comes to making this fabric. These machines are designed to produce premium quality Meltblown Nonwoven Material with accuracy and effectiveness.

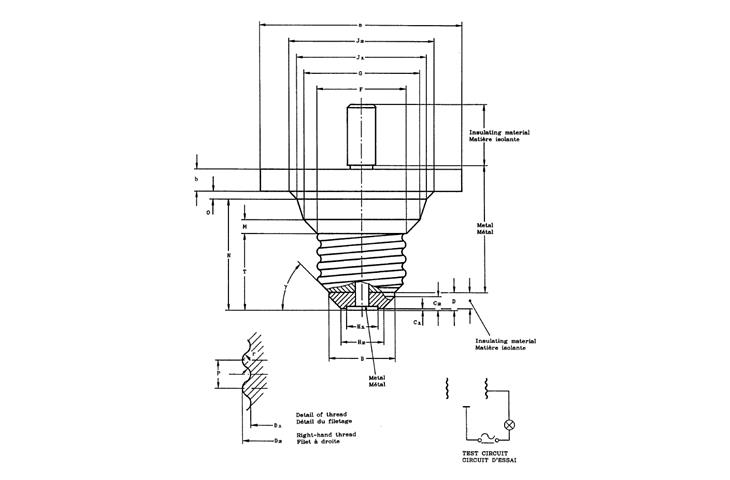

It’s got a few primary components: an melt pump to fuse the material, a spinneret to make the fibers, a drawing unit to strengthen them, and a receiving unit to assemble them into a whole. The melt pump turns the resin into a fluid, which then passes through the spinneret to produce ultra-fine filaments. The drawing unit makes the fibers stronger and better at filtration, and the receiving unit brings them all together to make the ultimate material.

3. Advantages of Meltblown Filter Nonwoven Fabric Machines

These machines are a significant victory for everyone involved, from the manufacturers to the users. First off, they continue to manufacture the same great premium material over and over, so the final consumers get stuff that’s meet standards.

And they’re efficient too, which means they can make massive fabric production without reduce waste. They’re also pretty simple to operate and servicing, which means minimal downtime and enhanced efficiency. And last but not least, they can handle diverse materials, so they’re really versatile applications.

4. Safety and Environmental Considerations

Safety and being eco-friendly are super essential when you’re running the machine. You gotta comply with protocols and use appropriate safety gear to maintain safety.

They’re also constructed to use fewer materials and energy, which is benficial to the Earth. Caring for properly of them and checking them out regularly keeps them running over an extended period.

5. Customer Success Stories

We’ve got customers across the board deploying our systems. A prominent mask manufacturer started deploying our systems and said their production increased and their product quality improved.

A company that makes defensive equipment said our machines are exceptionally strong and reliable. These stories show just how superior and flexible our machines are.

If you interested in further details about these machines and what they can do, check out these resources:

- “An In-depth Manual on Meltblown Nonwoven Fabric” by John Smith

- “Technological and Scientific Aspects of Nonwoven Fabrics” by Jane Doe

- “Meltblown Filter Nonwoven Fabric Machine: A User’s Manual” by Mark Johnson