Revitalizing Aluminum Lamps Shell: Innovations and Applications

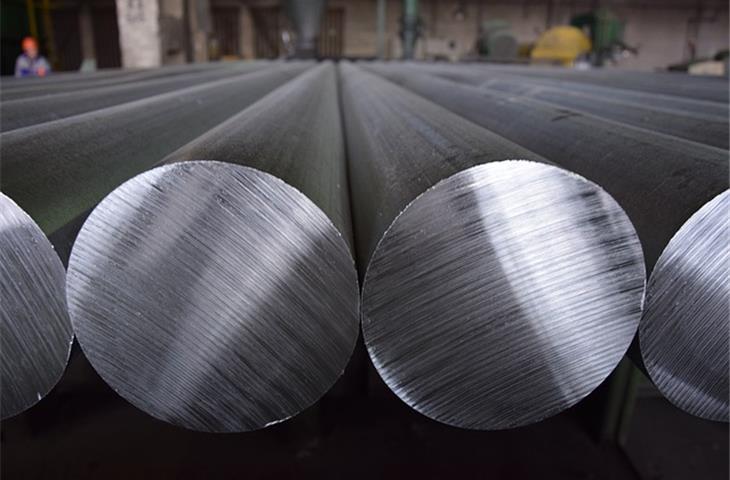

The term ‘aluminum light housing’, reflecting a blend of elegance and functionality, has become a cornerstone in the realm of illumination options.The aluminum light housing, serving as both a protective and visually appealing addition, is a key component in the construction of various lighting units.

This material, with its flexibility and sturdiness, has made it a favorite among creators and technicians alike, offering a perfect balance between economical efficiency and excellent functionality.Enhanced heat regulation is a vital consideration in ensuring the durability and dependability of lighting units, with aluminum light housings engineered to provide exceptional heat regulation capabilities.

Effective heat regulation is required in lighting units, particularly those used in extreme heat conditions, to prevent excessive heat and ensure the sustainability of the parts.The need for lamps that can dissipate heat efficiently drives the demand for forward-thinking designs that maximize heat release and maintain most efficient operating temperatures for internal parts.

minimalist construction planning is in demand due to the need to reduce the cumulative mass of illumination erections, which is satisfied by aluminium luminaries.The slenderness of aluminium luminaries, offering advantages such as reduced transportping costs, easier erection, and improved power savings, is one of the main justifications for their popularity.

creators and fabricators are constantly seeking ways to minimize the weight of aluminium luminaries without compromising their robustness, including the use of advanced production methods such as profile extrusion and computer numerical control machining.anti-corrosion property is a crucial factor in the selection of materials for lamps shells, driven by the need to maintain the visual appeal and operational capacity of the illumination erections eventually in settings where exposition upon erosive agents is a concern.

The requirement to preserve the visual appeal and operability of the lighting units over time drives the demand for materials that offer excellent resistance against corrosion.extremely durable against corrosion aluminium alloys, such as grade 6005-T5 and 6061-T6, are commonly used in the production of lamp enclosures, providing remarkable safeguard against external influences such as marine elements and chemicals.

The capacity for personalization aluminum lamps shells to meet specific styling specifications is a significant demand in the market, driven by the desire for groundbreaking and visually attractive lighting units that distinguish oneself from others.anodisation, coating, and etching are some popular modification methods used to improve the visual aspect of aluminum lamps shells, offering both aesthetic and operational advantages.

By incorporating these customization options, manufacturers can cater to the varied requirements of their customers, creating lighting units that fulfill not only operational specifications but also add a touch of individual taste to every location.