Promo: Top 5 Rubber Inspection Equipment Must-Haves

You know, when you’re all about making sure your elastic material stuff is top-notch, getting the correct implements for the task is really crucial. These implements are super important. These help us spot any outer imperfections and make sure everything is the correct density, from initiation to completion in making elastic material stuff.

Ultrasound Inspection Gear

Sonar gear is a total breakthrough in elastic material making. It’s a non-invasive kind of inspection. These apply these high-frequency acoustic waves to detect any voids or empty interior voids within the elastic material.

The most notable aspect? It can detect all problems without altering the rubber’s quality. Take, for instance, a bustling factory line. This equipment can identify issues early, saving time and money by avoiding the need for later repairs. As reported by some sources at MarketsandMarkets, this market for ultrasound equipment is expected to expand considerably, at a rate of 6. 6% annually from 2020 to 2025.

Thermal Imaging Cameras

These thermal imaging devices are becoming quite common in the rubber industry. They utilize infrared technology to detect temperature variations. This indicates to us if the rubber is curing uniformly or not, which is extremely crucial to prevent areas of weakness.

By employing this technology enables manufacturers to identify problems early, resulting in significant cost savings in the long haul. Take a look at this fascinating story from the Rubber Manufacturers Association. A major tire manufacturer employed thermal imaging to reduce their defects by 30 percent on the production line.

Visual Inspection Gear

Visual inspection gear is still super important in the rubber world. That means things like magnifying devices, plus other advanced tools to check the rubber for surface defects.

It’s affordable and straightforward, so it’s a essential for making sure the quality is on point. Some folks at rubberinspection. Com talked about a system that’s really good at finding tiny visible problems that might normally slip by.

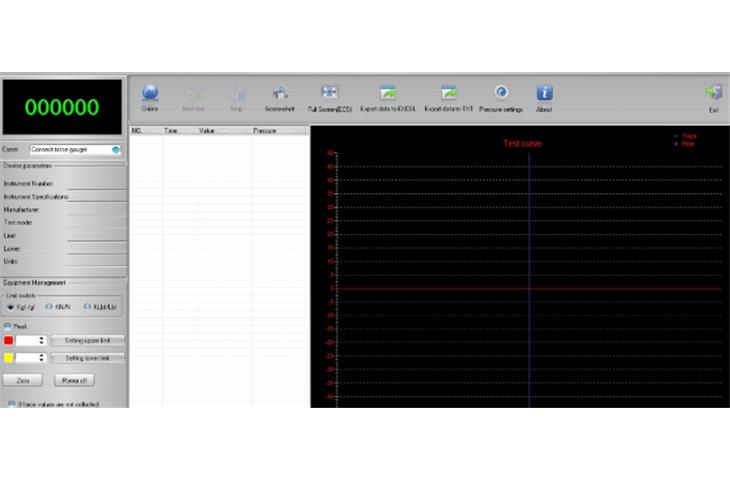

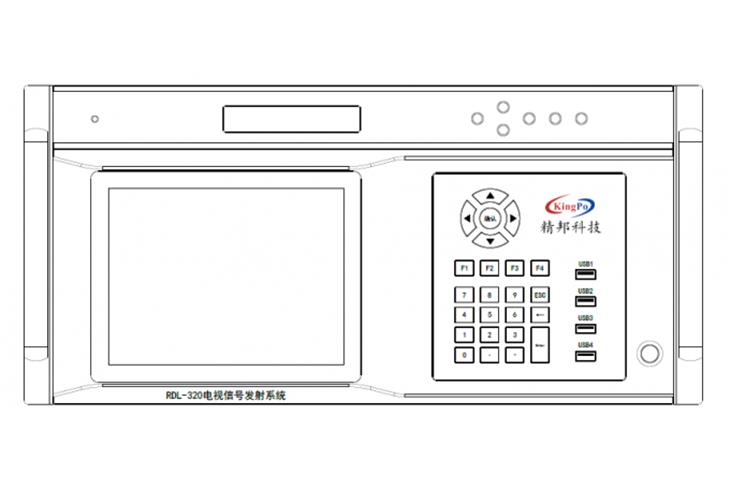

Thickness Gauges

You can’t live without thickness gauges when you need to keep uniform rubber thickness. They come in various types, like mechanical and digital, and they’re used to determine the thickness of rubber sheets, sheets, rolls, or custom shapes are.

Keeping the thickness consistent is very important for how quality of the product and performance. There’s this interesting account on rubberinspection. Com about a company that used thickness gauges to improve their products and satisfy customer requirements.

Surface Profilometers

Area irregularness Meters are all about verifying how even or irregular the area of rubber is. This is really critical for stuff like tyres or conveyor belts thon need to look or feel a certain aspect.

It uses a small device to examine the area and make a image of it to verify for some irregularities or jitters. An authority on rubberinspection dot com observed thon implementing area irregularness Meters facilitoned a business lower their amount of failures with twenty-five percent.