Mastering the Safety Glass Drop Impact Tester: Ensuring Structural Integrity

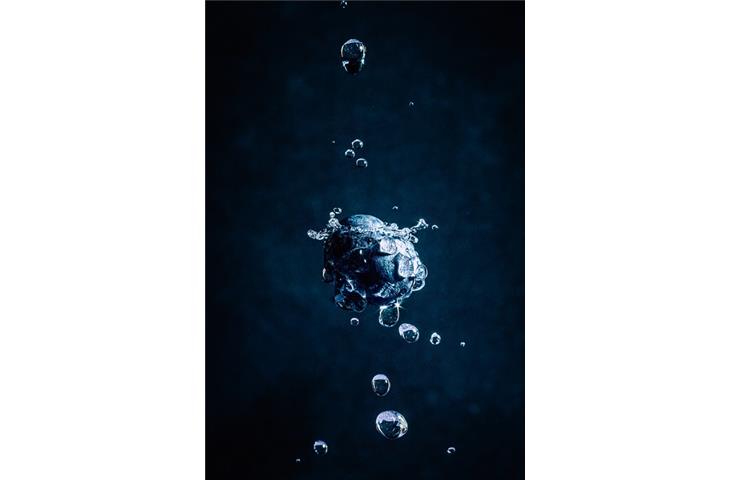

In the production and quality assurance sectors, the shatterproof glass drop falling impact tester, which is a essential piece of equipment, is used to assess the resistance of shatterproof glass under mimicd real-life conditions.This advanced device, which mimics the impact of a falling item on glass surfaces, provides useful information into the material’s capability to endure such stresses without fracturing.

We will delve into the significance of the shatterproof glass drop falling impact tester, explore its various applications, and discuss the essential requirements for its effective operation in this article.To confirm that the testing outcomes are trustworthy and uniform, one of the primary demands of a shatterproof glass drop falling impact tester is the ability to accurately determine the falloff height.

A precise altitude gauge or detector, which can determine the height from which the item is dropped with minimum inaccuracy, must be equipped with the device.This confirms that the testing parameters are uniform over various testing iterations, enabling accurate analyses and examination of the glass’s operation.

Another essential part of the drop impact testing device is the impact simulation system, which must be designed to reliably and consistently recreate the collision of a descending item on the windowpane.This includes the ability to adjust the weight and speed of the descending item, as well as the angle of collision.

A sturdy and resilient mechanism is essential to ensure that the tester can withstand continuous usage and maintain its consistent precision.The drop impact testing device must be capable of collecting and analyzing data during the testing process.This includes the ability to document the elevation of the drop, the speed of the descending item, and the subsequent harm to the glass.

The device should be equipped with a high-definition camera or other visual recording device, which is used to record comprehensive visuals of the windowpane before and after the impact.Additionally, the tester should have a intuitive control panel, which allows for easy information entry, retention, and examination.A drop impact testing device is only as effective as its users; therefore, it is essential that the device is designed with the final consumer in mind.

This includes a friendly interface, clear directions, and intuitive controls.The tester should be simple to set up, operate, and maintain, even for users with limited technical skills.A well-designed device can help ensure that the testing process is efficient and that the findings are correct and reliable.

For ensuring the structural integrity of safety glass in multiple uses, the safety glass impact testing device is a vital instrument.By meeting the demands of correct drop height measurement, a solid drop drop impact mechanism, efficient data gathering and analysis, and a friendly design, this device can provide useful insights into the performance of safety glass under simulated actual use conditions.

As the demand for high-grade, long-lasting safety glass continues to grow, the significance of the safety glass impact testing device will only increase, making it an essential instrument for manufacturers and quality assurance experts alike.