Innovating with Testing Equipment: A Manufacturer’s Insight

Well, I’ve been around the testing instruments sector for a while. It’s changed a lot over the years. There’s always been a high demand for highest-quality, reliable testing gear. My job is to ensure that we supply apparatuses that all engineers and scientists around can rely on.

What are some of the biggest hurdles in creating state-of-the-art testing equipment?

How do you make sure your gear lives up to international standards?

What’s new in the testing equipment game these days?

How do you turn customer feedback into improvements for your products?

Got any cool stories about your testing gear being a hit in different fields?

What are some of the biggest hurdles in creating state-of-the-art testing equipment?

Creating top-notch testing equipment is not an easy task. You must have knowledge of the technology, and have well-constructed testing plans, and prioritize quality as a primary consideration

The challenge is ensuring that it is extremely accurate and dependable, while also being user-friendly. I have been involved in projects where it was necessary to incorporate intelligent sensors and sophisticated software to provide up-to-date information. That is a challenging task.

How do you make sure your gear lives up to international standards?

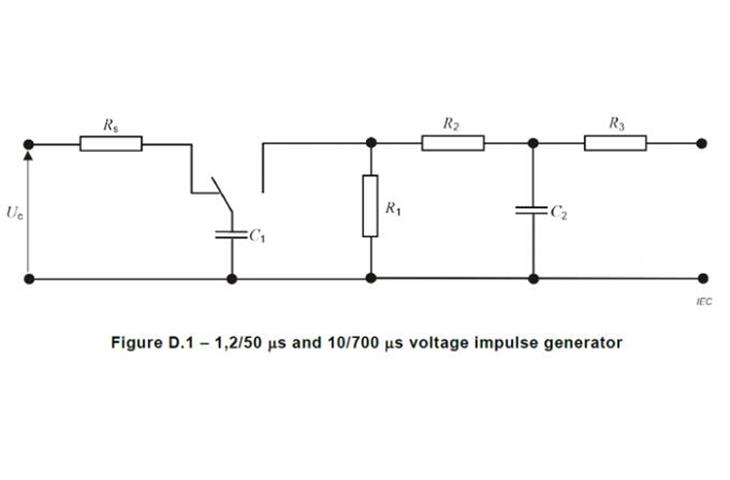

Sticking to global standards is a must for us. We follow the regulations established by organizations like the IEC and ASTM.

We subject our equipment to rigorous testing and get it certified to meet the standards. Lately, we had our gear checked by a external entity to meet International Organization for Standardization (ISO) requirements. It was difficult but necessary.

What’s new in the testing equipment game these days?

The testing machinery industry is constantly evolving. A major trend lately is incorporating the Internet of Things (IoT) technology.

Linking equipment to the internet lets us do instantaneous analysis and distance monitoring, extremely convenient for the users of our equipment. Another neat thing is implementing artificial intelligence (AI) and machine learning to forecast the performance of the equipment and what it needs for maintenance. That’s a significant time-saver.

How do you turn customer feedback into improvements for your products?

Customer comments is extremely important to us. We proactively request for feedback from our customers and we use that to improve our products.

So, such as, we got feedback saying our the software was complex, so we completely redeveloped it to make it easier to understand. This has really helped us create a reputation for being centered on what the customer needs.

Got any cool stories about your testing gear being a hit in different fields?

Our testing equipment has found its way into all sorts of industries. Such as, in the automotive industry, our equipment has been a major assistance for manufacturing companies to keep their vehicle quality and safe.

In the pharmaceutical industry, our gear has been key to drug development and ensuring quality assurance. These examples of success really speak to the reliability and quality of our gear.