In-Depth Look at Four-Point Bending Machines

Forming and contouring metal parts, the quadrilateral bending machine stands as a vital tool in the realms of metals manufacturing and accurate engineering.This piece of equipment, which is designed for bending metals including steel, aluminum, and copper with exactness and effectiveness, is versatile.A controlled application of pressure by it allows the creation of complex shapes and angles which are vital across multiple sectors, including automobile, aeronautical, and building.

We will delve into the four key demands associated with the quadrilateral bending machines to explore their significance in modern metals manufacturing.A primary demand of a four-point bending machine is to deliver exacting precision and stability in the bending procedure.In industries where the slightest deviation from the intended form or angle can lead to product non-conformance or safety risk, this is crucial.

A requirement of the device is to be capable of keeping exact specifications and producing consistent outcome across multiple curving tasks.In order to accommodate to a considerable variety of uses, the four-point curving device should be flexible in dealing various kinds of substances.Without sacrificing its stability, the device must be capable of curving substances of varying thicknesses, breadths, and stiffness.

Given the nature of alloy fabrication, the preference is security. A four-point curving device must have its layout with security systems that protect both the user and the tooling.This includes the implementation of urgency shut-off devices, protection devices, and easy-to-use manipulators, with an additional requirement of being accessible to allow users of varying ability levels to operate it both effectively and securely.

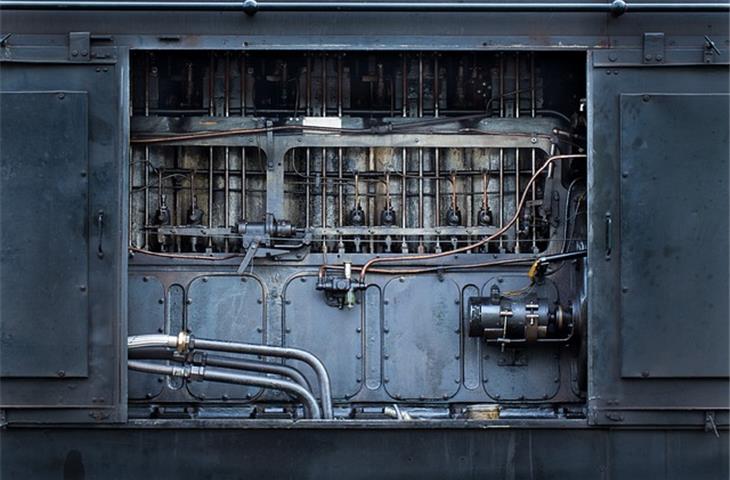

To guarantee long-lasting performance, a four-point bend machine should be constructed with a sturdy design and superior quality parts.continuous running should be machine-endurable, not withstanding extreme wear or breakdowns.ensuring production timelines and minimizing downtime is crucial because of this reliability.

In detail, we will investigate these requirements, providing insights on how a four-point bend machine meets the challenges presented by contemporary metalworking.Furthermore, we will discuss the benefits of using a four-point bend machine aacross various applications, along with the factors that should be considered while selecting the machine suited to specific needs.