Hydrostatic Pressure Test Machines: Essential Demands and Applications

In the engineering sector, hydrotest machines are crucial tools. They are used to verify robustness and longevity of multiple parts and constructs.To evaluate tensile durability of materials, such as pipes, tanks, and valves, to withstand pressure without failure, these machines impose a precise measure of pressure.

This article will explore the essential demands and applications of hydrotest machines. It will highlight their importance in ensuring safety and reliability in various commercial sectors.The primary demand of a hydrostatic pressure test machine is the ability to accurately measure and control the pressure applied to the test subject.

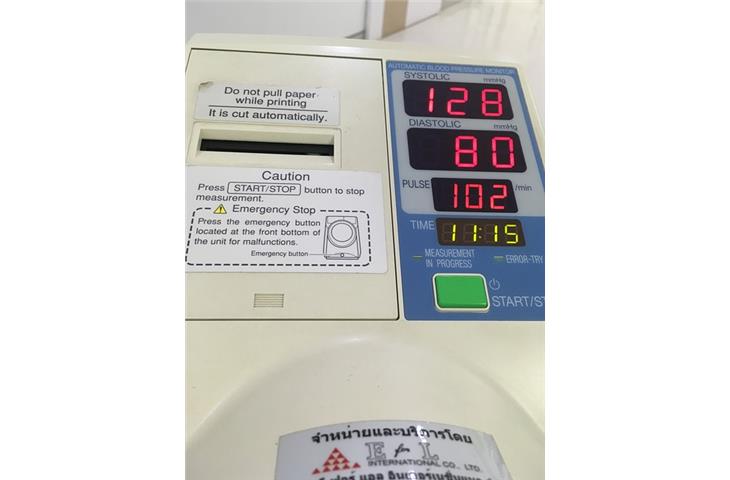

This is essential to ensure that the testing outcomes are reliable and can be used to make well-grounded conclusions about the behavior of material.The following are some key aspects of accurate pressure monitoring and regulation.exact pressure gauges are required for measuring the pressure applied to the test subject with negligible inprecision.

Sturdy pressure Regulatory systems are necessary for maintaining Uniform pressure throughout the Assessment procedure.Ongoing calibration of the Pressure meters and Regulatory systems is crucial for Guaranteeing Continuous precision.Using Hydrostatic pressure Testing machinery is a concern of Extreme importance.The following Safety mechanisms are essential for Safeguarding both the operators and the Test items.

These valves, known as Pressure relief valves, automatically release Surplus pressure to prevent damage to the test object or the Equipment itself.Fast access to Emergency shutoff buttons allows operators to shut down the Equipment in case of an emergency.A Secure and Anti-slip surface is necessary for preventing Incidents during the Assessment procedure.

Hydrostatic pressure Testing machinery should be Adjustable and compatible with various types of Test items.The Equipment should have an Adjustable Testing foundation that can Adapt to different Dimensions and forms of Test items.Flexible test programs allow for testing a wide range of Substances and environments.

A modular structure makes it simpler to update or substitute elements when required.For ensuring that users can easily set up and operate the hydrostatic pressure test machine, a intuitive design is vital.This includes:A unambiguous and simple operating panel with simple regulations and indicators is an intuitive operating panel.

Comprehensive computer assistance for setting up and performing tests, as well as for interpreting outcomes is computer assistance.Access to instructional guides and support for users to learn how to use the machine effectively is instructional guides.Hydrostatic pressure test machines play a critical function in ensuring the security and dependability of various elements and structures in the construction and production sectors.

By meeting the vital demands of precise pressure gauging and regulation, security measures, versatility, and user-friendliness, these machines can help businesses make well-informed choices and enhance their goods.The demand for excellent, long-lasting materials continues to grow, and the significance of hydrostatic pressure test machines will only rise.