Centrifuge Series: A Comprehensive Overview

Within the realm of manufacturing machinery, particularly in the centrifugal clarification sector, the term ‘Rotary separator series’ has become prominent.Famed for its groundbreaking design and sustainable operation, this series has garnered significant attention from engineering professionals and researchers internationally.In this article, we will explore the details of the Rotary separator series, and we will highlight its prime characteristics, uses, and advantages.

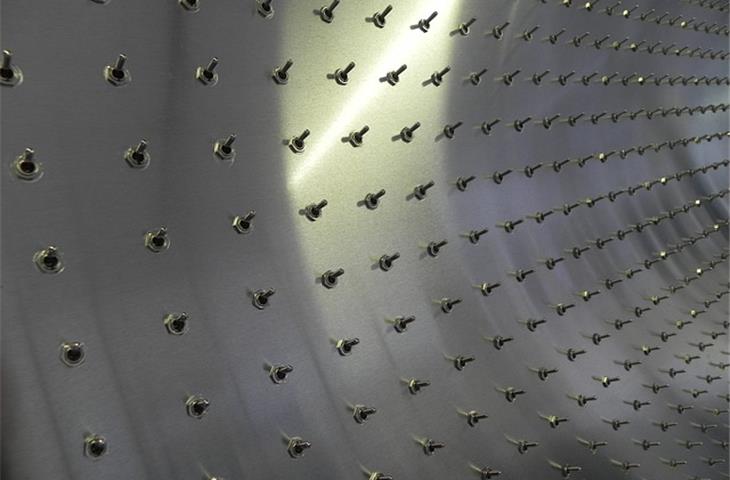

To provide a comprehensive overview, we will address the four pivotal elements pertaining to the Rotary separator series: engineering and technology, uses, performance, and maintenance.Due to its cutting-edge design and advanced technology, the Rotary separator series stands out.Engineered to deliver exceptional separation performance, these separators are making them ideal for a wide range of uses.

The following aspects highlight the engineering and technology of the Rotary separator series:running at elevated RPMs, these separators enable the efficient disposal of particulate matter from fluids or fumes.Fabricated from resilient materials, the machines promote longevity and stability.Armed with user-friendly controls, the separators make it easy for users for alteration parameters and supervise the process.

By incorporating sophisticated energy conservation technologies, the centrifugal series reduces running expenses.The centrifugal series is multipurpose, finding uses in various industries, such as pharmaceutical products, food and drinks, chemical substances, and environmental fields.For separating APIs, centrifuges are used, which improves the purity of drugs.

These devices are employed for the purpose of separating solid matter from liquid substances, such as the partition of fluid product into rich part and watery part.Used for the purpose of separating chemical substancess, centrifuges minimize waste and improve quality of product.The centrifugal series is utilized to wastewater treatment, to separate pollutants from water, and to recover precious substances.

The exceptional operational excellence is one of the preeminent characteristics of the centrifugal series.The centrifuges achieve high partition efficiency to ensure the effective partition of particles from the mixture.Due to their ability to manage a wide range of viscosities, density, and temperatures, these devices are well-suited to various uses.

Offering speedy processing times, the Centrifuge series increases productivity in manufacturing environments.Due to their design for reduced maintenance, these machines shorten downtime and running costs.To ensure best performance and durability, maintaining the Centrifuge series is crucial.The following care advice will help you keep your centrifuge running smoothly:

Regularly clean the centrifuge to eliminate any particles or impurities that may affect its performance.use lubrication to moving parts, as recommended by the manufacturer, to reduce wear.Regularly perform inspections to identify any possible problems before they result in downtime.Ensure that operators are trained on proper handling and maintenance procedures, to avoid accidents and damage.

With its innovative design, advanced technology, and exceptional performance, the Centrifuge series has revolutionized the centrifugal separation industry.Due to its versatility, wide scope of applications, and economical operation, the Centrifuge series is an essential asset for various industries.

This article aims to provide a thorough summary of this striking collection of centrifuges via discussing its construction and technology, uses, functionality, and upkeep considerations.