Call for Toughened Glass Testing

You know, is a for safety and . This strong stuff is super in , , and . But how do you make sure the you’re using is ? Let’s jump into the in , and I’ll .

Number one: making sure it’s up to international standards.

Number two: quality control during making.

Number three: how tough it is and how well it handles impacts.

Number four: testing how the glass holds up in different environments.

Number five: making sure customers are happy and trust the product.

Number one: making sure it’s up to international standards.

A main reason to assess strengthened glass is to guarantee Conformity with Global Norms. Norms such as ASTM and EN establish the fundamentals, right?

Like, For example, the ASTM C 1048 specification informs us which strength and surface quality we require. By adhering to these guidelines, manufacturers can ensure their products is secure and reliable.

Number two: quality control during making.

Quality inspection is crucial when producing strengthened glass. Routine inspections aid in identifying any issues, so that only the quality items make it to the market.

For example, they subject to heating and cooling the glass rapidly to determine if it will crack or shatter. In this manner, it is unnecessary for them to withdraw their product from the market, and everyone is satisfied.

Number three: how tough it is and how well it handles impacts.

One cool thing about reinforced material is that it’s extreme robust and good at dealing with collisions. Experiments make sure the material can cope with tough elements and accidents.

For example, they drop a steel sphere on the material to see how it does in a actual kind of way. The material has to take the hit without chipping or breaking to pass the test, showing it’s really sturdy.

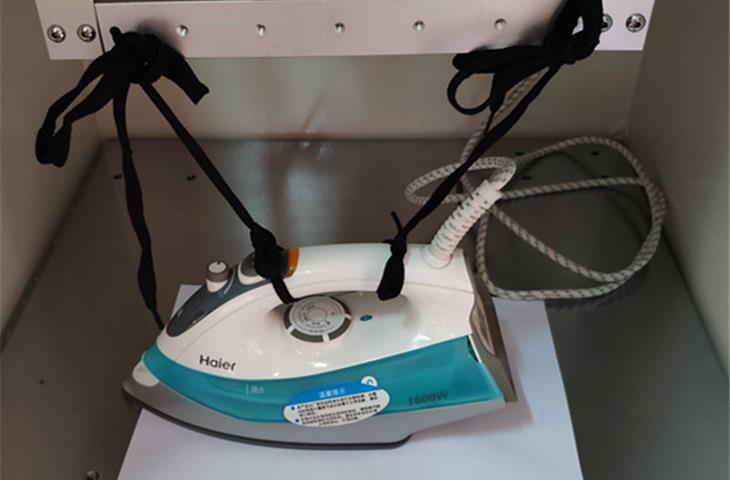

Number four: testing how the glass holds up in different environments.

Weather elements can really mess with how reinforced material works. So, we need to test it in all sorts of environments, like extreme hot or extreme cold, and lots of humidity level and ultraviolet radiation. This testing helps manufacturers make material that works excellent for all sorts of applications, like outside sitting furniture or car panes.

Number five: making sure customers are happy and trust the product.

Ultimately, it’s all about ensuring clients are satisfied and trust the glass. Through demonstrating that the glass is of high quality, manufacturers can inform clients their stuff is secure and reliable. This can contribute to increased sales and keep clients returning.