Optimizing Battery Pack Testing Machine Efficiency

Hey, ever think about how those battery pack testing machines actually function? They are like the core—super Critical for battery operation and security! I’m gonna talk about five major subjects regarding battery Inspection process. I’ll give you some useful information and tips.

First up, let’s talk about the different kinds of battery pack testing machines.

Next on the list is why regular testing is such a big deal.

Then we’ve got the testing techniques that everyone should know.

We should also talk about all the cool equipment that makes testing possible.

And last but not least, the software that helps makes sense of everything.

First up, let’s talk about the different kinds of battery pack testing machines.

There are lots of different types of battery pack testing machines, and each one is made for something particular. Common ones are resistance testers, load testers, and capacity testers.

Resistance testers measure the internal resistance of a battery, while load testers check the battery’s ability to deliver power under load. Capacity testers, on the other hand, determine the total amount of energy a battery can store. Knowing these types makes it easier to select the right machine for your requirements.

Next on the list is why regular testing is such a big deal.

Regular testing is a must to make sure your battery packs are working great and are secure. According to a report by the International Energy Agency (IEA), battery packs that are not regularly tested can experience a significant decrease in their service-life. But if you test them regularly, you can detect any problems early and save money on maintenance too.

Then we’ve got the testing techniques that everyone should know.

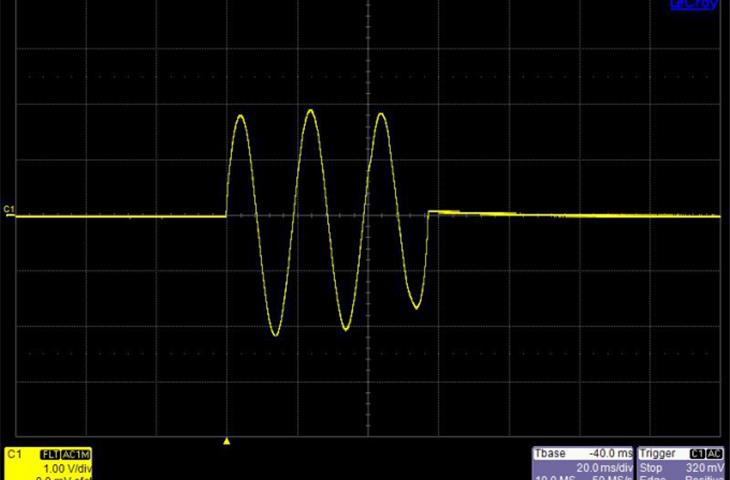

There are quite several methods to test batteries, like cyclic voltammetry (no synonym needed, as it’s a specific term), galvanostatic charging-discharging, and Impedance spectroscopy (no synonym needed, as it’s a specific term). Cyclic voltammetry (no synonym needed, as it’s a specific term) assesses the current-voltage properties of a battery under multiple conditions, while galvanostatic charging-discharging consists of recharging and discharging the battery at a constant flow.

Impedance spectroscopy (no synonym needed, as it’s a specific term) is all about determining amount of energy the battery won’t give out and how that changes if you change the energy level. Familiarity with these methods makes it easier to pick the correct approach to test your battery’s particular requirements.

We should also talk about all the cool equipment that makes testing possible.

Using the right gear makes testing your battery really accurate and efficient. You need some essential equipment for this, like a battery charging system, a multipurpose meter, and a data collection system.

A battery charger is employed for recharge and discharge the battery while under test, while a multimeter measures the voltage, current, and resistance of the battery. The data acquisition system monitors your test findings and assists in interpreting them. Acquiring superior equipment can lead to the entire testing procedure much more precise and reliable.

And last but not least, the software that helps makes sense of everything.

The most recent battery pack systems are equipped with exceptionally advanced software that assists in determining what the test findings mean. The software generates comprehensive reports, monitors how your battery performance over time, and can even give you a warnings for any issues. With this software, you can lead to smart choices on the optimal time for maintenance or replacement of your batteries.