China Fabric Testing: Navigating the Quality Path

The country, you know, is a major player in the textile industry, making all various fabrics for different places. It’s super important for everyone, both the makers and us buyers, that these fabrics are high-quality materials. We’re diving into five important issues about how the country tests its fabrics. We want to give you the inside information on ensuring these fabrics are of high quality.

1. So, what are the big rules for testing fabrics in China?

2. Alright, how do they actually test these fabrics?

3. So, what are the hard parts about testing fabrics in China?

4. So, how can the folks making these fabrics get better at testing them?

5. What’s so great about having good tests on China’s fabrics?

1. So, what are the big rules for testing fabrics in China?

China fabric testing adheres to a variety of international and domestic criteria. There are these international standards, like ISO standards, like the ones for preventing color bleeding and making sure things are really excellent quality.

And then there’s this GB standards, China’s own rules, which a lot of people use, too. Like, there’s this GB/T 3920. 1-2013 standard thing, it’s about fabric strength during tension.

2. Alright, how do they actually test these fabrics?

They typically begin by sampling a small piece of fabric, preparing it, and then performing the tests. They must ensure the fabric under test matches the entire batch.

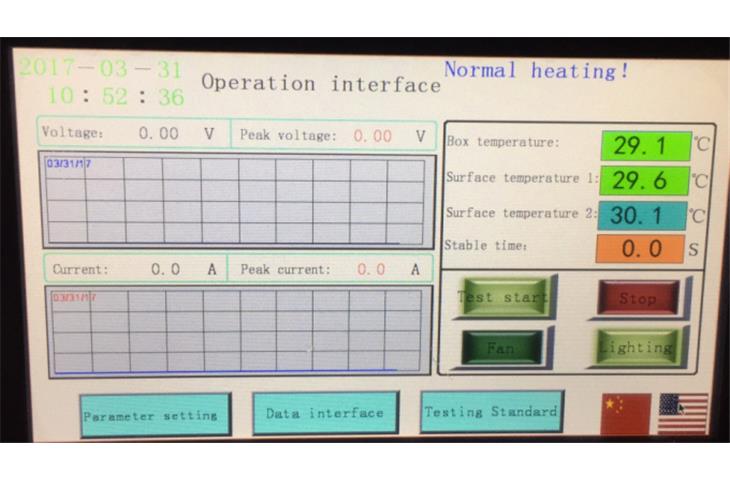

They could cut the material into small squares or prepare it for unique tests. Then they perform multiple tests to determine its strength, the extent of its shrinkage, the color retention, and its flammability resistance.

3. So, what are the hard parts about testing fabrics in China?

The point is, there are numerous types of fabrics with their unique properties. Every type of fabric requires its own testing method.

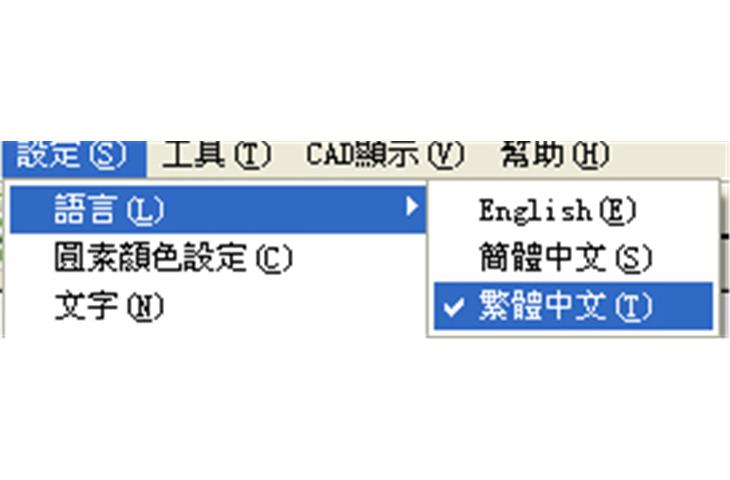

And it is challenging to ensure all labs conduct the tests consistently. Also, linguistic issues various approaches may hinder, particularly when involving international personnel.

4. So, how can the folks making these fabrics get better at testing them?

They could increase expenditure on high-end testing equipment and teach their workers how to operate correctly. Working with reputable laboratories and following quality standards like ISO 9001 certification could help, too. They should constantly review their work and always look for methods for improvement.

5. What’s so great about having good tests on China’s fabrics?

Carrying out robust tests on the fabric makes sure the product quality is high and makes customers satisfied with the product and the brand. It also saves them from making bad stuff that can incur significant expenses to repair or recall. And it helps companies have confidence about selling in new places because they know their stuff complies with all regulations and standards there.