Why Testing Foam Height Matters: Insights from a Pro

You know, being in the foam height testing biz, I’ve really seen just how significant it is to master this stuff. Whether or not you’re within the manufacturing field or just want to make sure your foam stuff is satisfactory, here are five important factors to take into consideration.

1. Accurate Measurement

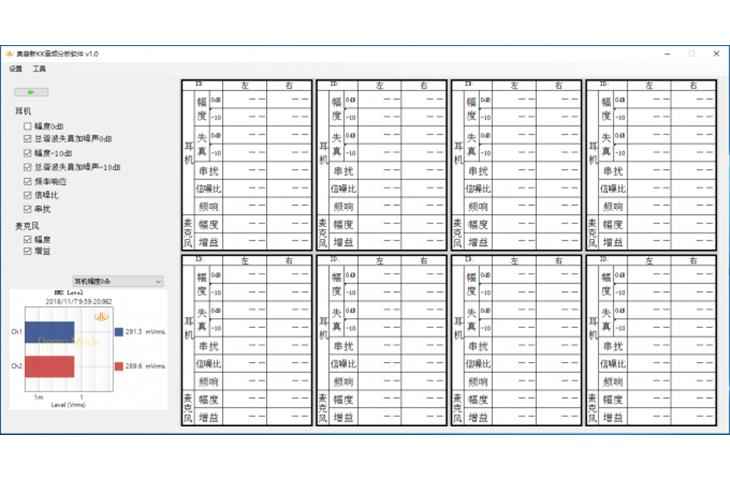

Exact measuring is the whole deal in foam height testing. From what I’ve seen, you must be exact, or else your stuff won’t be up to standards of industry benchmarks or what clients expect. It’s all about having the adequate Instrumentation and people who really get the execution of the test in depth.

2. Equipment Calibration

Routine maintenance of your test equipment is crucial for keeping it accurate. Over time, machines can become inaccurate, and that means you might get dodgy data. I’ve seen companies get way better data from their foam level measurement after setting up a solid calibration routine.

3. Data Analysis

Collecting data is just the start. The true essence is in figuring out what that data means, spotting trends, and nipping problems in the bud. I’ve taught teams how to make interpretation of their data, which helps them make smarter choices and tweak their procedure.

4. Quality Control

Quality control is a major concern in foam level measurement. Making sure each foam piece hits the mark means less unnecessary expenditure, happier clients, and a competitive advantage.

5. Regulatory Compliance

You just gotta comply with rules and regulations in this game. No matter what if it’s safety guidelines or product-specific matters, foam elevation testing is a must for numerous businesses. I’ve assisted clients determine the regulations and ensure they remain compliant of them.