Revolutionizing Foam Quality with Upgrade

Ever since I first got my hands on that excellent foam testing equipment, I’ve been addicted to the whole process. These places are all about producing top-quality gear, and they’re very crucial because they make sure our typical foam items are of good quality. Today, I want to plunge into the interesting field of those factories and chat about the main topics that define what they are.

First up, let’s talk about why quality control is a big deal in making foam stuff.

Next on the list is the cool stuff happening in foam testing tech.

Now, let’s talk about factory certifications and partnerships, which are a big deal.

Next, let’s chat about training and support for users, which is super important.

Last but not least, let’s talk about the future of foam testing.

First up, let’s talk about why quality control is a big deal in making foam stuff.

As someone who’s worked in the industry, I’ve seen hands-on the impact of quality assurance on foam products. Getting good foam testing equipment is key to making sure each production run of foam is sufficiently good. This not only guarantees the security and ease of purchasers but also helps avoid costly product recall and reputation harm.

Like when I was working on a project, we had to change to a new supplier for our foam material. The first deliveries we received were inuniform, leading to problems in the final product.

But once we moved to to a supplier with really high-tech testing equipment, the foam standard level and uniformity got a lot better. That occurrence showed us how important it is to have reliable equipment and the manufacturing plants that make it.

Next on the list is the cool stuff happening in foam testing tech.

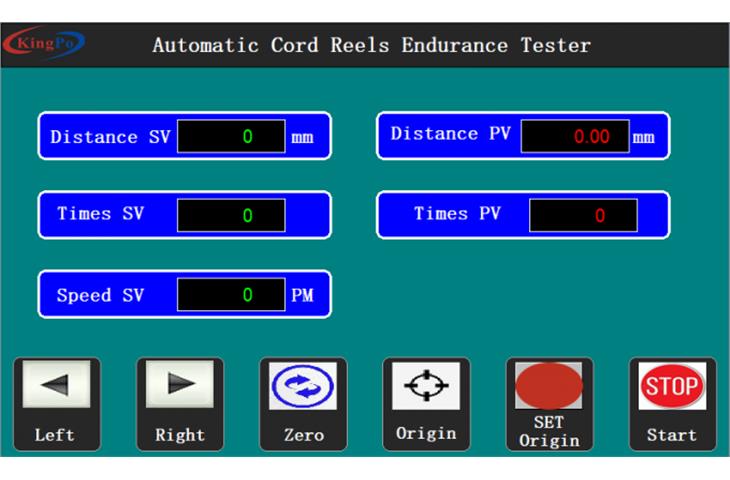

Foam examination is always evolving, with all sorts of innovative technology and approaches coming along to make sure the findings are spot-on. One neat advancement is using automated rebound testing machines. They’re quicker, highly accurate, and way easier to read than the traditional methods.

I got to see this exciting developments in action at one of those foam manufacturing facilities. They had this super cool automated testing device that gave us live data and automatically analyzed it all.

It saved time and effort and made the whole testing process way more efficient. That shows how committed those factories are to keeping Foam examination tech on the state-of-the-art.

Now, let’s talk about factory certifications and partnerships, which are a big deal.

<manufacturing certifications are a vital element when selecting high-standard foam compression testing machine. These certifications, such as International Organization for Standardization guidelines, ensure that the factories comply with strict standard of quality and safety, giving customer confidence. Moreover, partnerships with reputable research organizations and universities play a important contribution in driving innovation and ensuring that the machine remains at the forefront of foam assessment technology.

<pIn my perspective, the factory we worked with had several accreditations and partnerships. This not only confirmed their devotion to quality but also provided us with a wealth of information and assistance to help us improve our foam production methods.

Next, let’s chat about training and support for users, which is super important.

<pHaving superior foam testing equipment is just the start. Making sure users receive training and supported properly is key to getting the most out of that gear. Lots of those manufacturing facilities offer education courses, training workshops, and all sorts of customer service to help users make the most of their gear.

<pI recall when I initially employed foam rebound testing machinery, I had lacking knowledge on what to do. ,,。,。

Last but not least, let’s talk about the future of foam testing.

<<pThe future of foam testing is really cool, with innovative strategic technology and advancements just immediate result. From AI and state-of-the-art AI and ML technologies to those automatic testing systems, these manufacturing facilities are about to totally reinvigorate the foam testing market. As an veteran professional, I'm revitalized to see the influence of these technologies on how we make manufactured foam materials and keep quality constancy ensured.

<pSo, to conclude, those premiere foam testing equipment manufacturers stand out prominently within the industry of foam testing. They're committed to excellence, pioneering, and determined to please clients, so they're significant advantage to enterprises and end-users alike.