Mastering the Art of Hydrostatic Pressure Testing

These hydrostatic pressure tester machines are super vital across various sectors, from vehicles to aircrafts. They’re really robust and constructed to see how materials withstand under super high pressure, which helps ensure safety and dependability. In this piece, we will discuss the key five aspects common questions regarding The equipment, providing some advice and techniques to help you master hydrostatic testing.

Number one, it’s all about calibrating and keeping these machines in good shape.

Number two, versatility is a big deal when it comes to what these machines can do.

Number three, safety first—these machines come with safety features to keep you out of harm’s way.

Number four, these machines can be a good deal on the wallet.

Number five, you need some training and support to really get the most out of your machine.

Number one, it’s all about calibrating and keeping these machines in good shape.

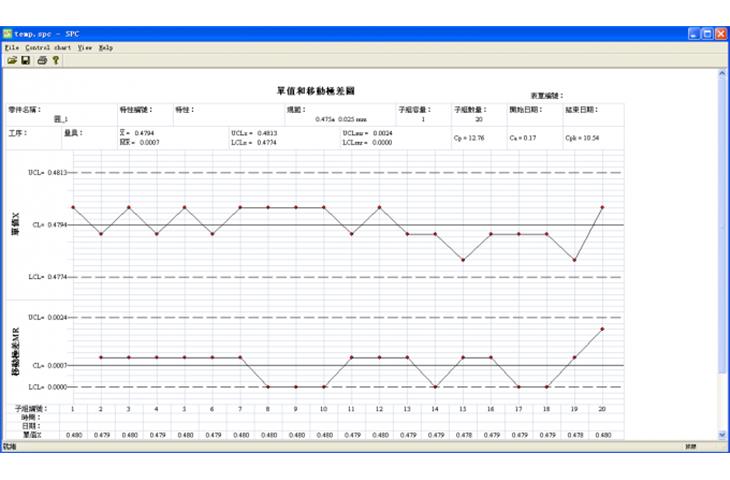

Accurate calibration and regular maintenance are crucial for hydrostatic pressure tester machines. Calibration ensures that the machine provides precise and reliable results, which is necessary for upholding the quality and safety of your products.

Regular care keeps the machine kicking for longer and helps you save money in the future on repairs. The folks at ASME say you should check the machine at least once a year to ensure it adheres to the guidelines.

Number two, versatility is a big deal when it comes to what these machines can do.

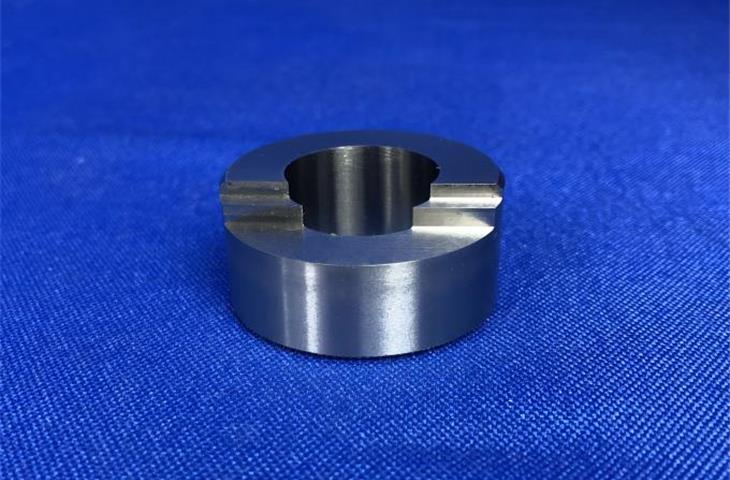

These pressure testing devices are super versatile. You can use them for various types of tests—like checking how robust and lasting items are, or making sure pressurized vessels don’t leak, and that fluid power systems are up to snuff. Take cars, for example—they use these machines to inspect fuel reservoirs and brake hydraulic lines for leaks. That flexibility means they’re super important for engineering professionals in lots of different fields.

Number three, safety first—these machines come with safety features to keep you out of harm’s way.

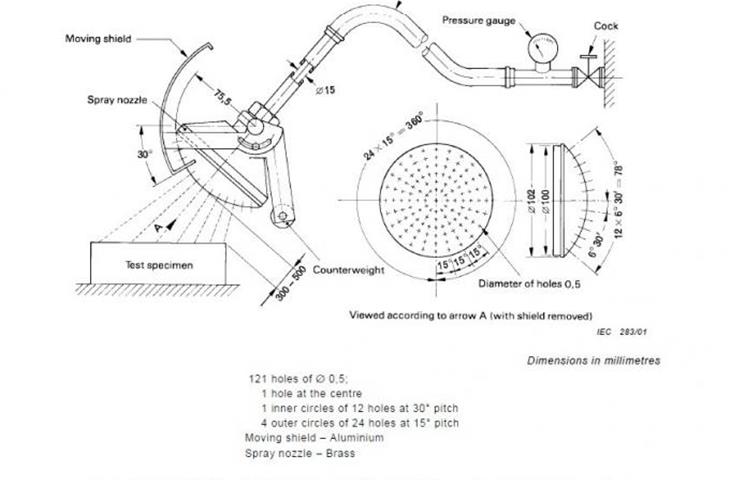

Safety’s super important with these pressure testing devices. They’ve got stuff like bleeding valves, gauges, and automatic stop functions to keep accidents under control.

Following the regulations—like International Organization for Standardization 17025 and American Society of Mechanical Engineers codes—is crucial for keeping your ensure product safety and superior quality. The Occupational Safety and Health Administration folks say you have to follow the safety regulations when you’re using these machines to keep everyone safe and prevent accidents.

Number four, these machines can be a good deal on the wallet.

These pressure testing equipment are a cost-effective way to test various materials and structures. Buying a good one can save you cash in the long run, since they don’t need to be fixed or replaced very often. According to a study, that if you keep one of these pressure testing equipment in in excellent condition, it can give you precise results for for more than a decade, so it’s a worthwhile investment for any business.

Number five, you need some training and support to really get the most out of your machine.

<p users should be familiar with how to operate the machines safely and properly. They gotta be comfortable with how the machine works, its safety mechanisms, and how to take care of it.

Most manufacturers offer instructional support so you can make the most of your machine. National Institute for Occupational Safety and Health says training is extremely important because it prevents accidents and makes sure the machines are used safely.