Innovative Textile Testing Instruments: Price-Driven Demands

Textile testing equipment are key for ensuring fabrics meet the standard and safe to use. The industry is continually evolving, and with it, we are seeing some emerging trends that are really propelling the advancement of these vital testing devices.

Number one on the list: super-precise and accurate testing.

Number two: designs that are a breeze to use.

Number three: gadgets that can do a whole bunch of tests.

Number four: portable gadgets that you can take anywhere.

Number five: gadgets that can play nice with data analysis.

Number one on the list: super-precise and accurate testing.

A significant issue that Many people demand in equipment for textile testing is extremely precise measurements. This is a essential requirement for manufacturers to make sure their stuff meets those strict regulatory standards set by the regulators.

Like, being able to measure how strong and stretchy fibers can be measured with exactness is really important for making robust and dependable fabrics. From my experience, I know it’s all about getting really superior equipment that gives you reliable results repeatedly.

Number two: designs that are a breeze to use.

Another big deal is making these gadgets easy to use. These testing devices are usually used by people who may not be very knowledgeable about technology.

So, it is highly crucial that these devices are user-friendly and understandable. For example, touchscreen systems have really made it easier to navigate and perform various tests. It’s not just speeded up the process but also reduced errors.

Number three: gadgets that can do a whole bunch of tests.

More and more manufacturers are after testing gadgets that can do a whole bunch of different tests. They want to ensure they can do a variety of tests without needing to buy loads of machines.

An excellent example is the all-in-one textile testing machine that can assess durability, how much it tears, and colorfastness, and more. This has really reduce on how much area and resources you need for testing.

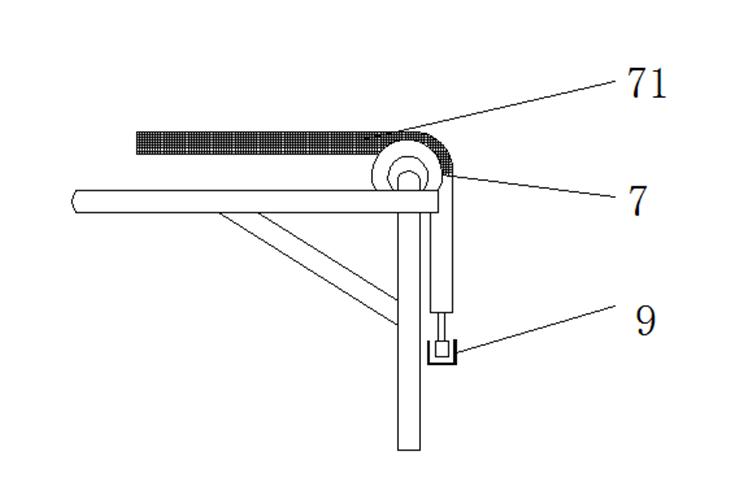

Number four: portable gadgets that you can take anywhere.

With the fabric industry going global, there’s high demand for portable testing gear. These gadgets are super important for inspecting on-site and making sure the quality is high, especially if you’re in remote locations. One recent success is a company that made a little, rechargeable testing device that’s really gained popularity with fabric businesses for on-site testing.

Number five: gadgets that can play nice with data analysis.

Another major development that’s really catching on is making these testing devices work with data analysis. This lets manufacturers analyze and interpret test data faster.

Using advanced data analysis software, companies can make informed decisions about how they make products and develop new products. This has been a real win for companies trying to get their supply chains in shape and increase efficiency.

If you want to learn more about textile testing devices, here are some materials I’d suggest checking out:

- Textile Testing: Principles and Processes by G. J.

Lienhard

- Textile Testing: A Hands-On Approach by John B. Szydlowski

- Textile Testing Instruments: Design and Construction by R. K. Kundu