Unveiling the Power of High Temperature Test Ovens

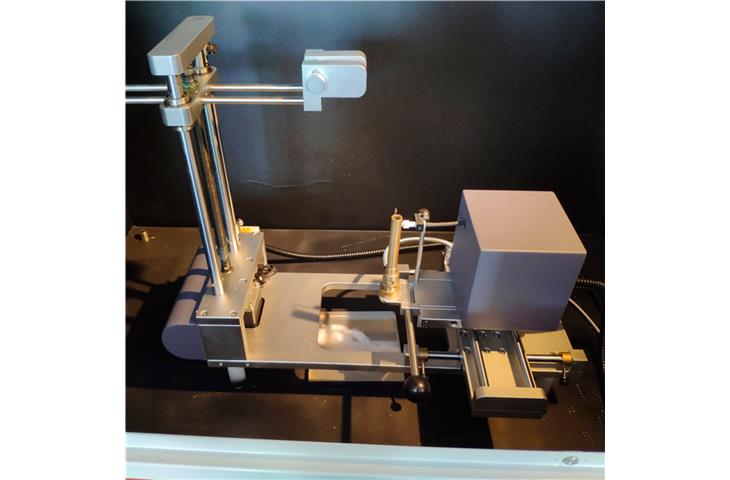

Greetings to all in the industrial sector! Have you ever pondered the operation of these high-temperature furnaces for testing? They resemble modern magic, really. These ovens are extremely crucial to ensure that items can withstand very high-temperatureeratures and rigorous tests. Alright, let’s dive into the world of high-temperature ovens and explore some fascinating aspects.

1. The Inner Workings of High Temp Test Ovens

4. New Tricks for High Temp Ovens

5. Where These Ovens Come Into Play

1. The Inner Workings of High Temp Test Ovens

So, heating chambers, or as some call them, temperature test ovens, are made to heat things up really bad. They’re widesely utilized, like in aerospace, automobile industry, and even electrical devices, to see how materials remain stable when it’s extremely high heat.

What makes these ovens so cool is they can keep the heat just right and distribute the heat uniformly. That means the tests you run are extremely precise and you can depend on the outcomes.

Like, I had this job at an aeronautical facility where we used these ovens to assess material heat resistance in planes. By heating the materials up real good, we knew they’d be tough enough to handle the extremely high heat air when the plane was flying.

2. Why Uniform Heat Matters

One big deal about these ovens is keeping the heat even all over the place. That means the heat inside needs to be the same no matter where you look, so the experiment outcomes are good. It can be challenging to make sure the heat is even, but it’s super important for tests to be reliable.

Let me share a personal story. During my employment at a laboratory, we experienced an problem with one of our high temperature test ovens.

The temperature uniformity was not uniform, which led to irregular test outcomes. We fixed the problem by figuring things out and making the right changes, and then the temperature was consistent again. That got us improved, more trustworthy results.

3. Safety First!

These furnaces can get extremely hot, like more than a thousand degrees, so they pose a risk. You gotta abide by the safety guidelines and wear the appropriate protective equipment to keep everyone safe. That means wearing gloves that are heat-resistant, eyewear to shield your eyes, and maintaining the furnace in proper condition.

I had a friend who forgot to use the right gloves and touched the hot oven. He received a burn, and it was a significant reminder to always exercise caution with these things. Safety is paramount, always adhere to the procedures!

4. New Tricks for High Temp Ovens

Those ovens are always getting better. New tech and improvements are coming out to enhance their performance, be increased precision, and simpler to operate. The latest development is sophisticated temperature control, automated testing, and Reducing energy consumption.

I saw one of those ovens that had a smart app such that you can inspect and modify stuff from your phone. So, you can Monitor the oven and change the settings Right through your mobile phone, Which is quite impressive as well as convenient.

5. Where These Ovens Come Into Play

Those ovens are used in many places in Multiple sectors. Some common uses include:

- Assessing heat resistance of materials in the aerospace and automotive industries

- Conducting thermal cycle testing to Mimic actual conditions

- Evaluating the performance of insulation materials in the construction industry

- Quality Assurance in the electronics and semiconductor industries

All these uses show how important those ovens are for making sure products are safe, Trustworthy, and Function efficiently.

Additional Information

- <a href='https://www. Sciencedirect.

Com/topics/engineering/temperature-control’>Engineering Temperature Control

- High Temp Oven Makers

- High Temp Oven Uses