Revolutionizing Plastics Pipe Integrity: Insights on Burst Testers

So, when we’re talking about strong and long-lasting polymeric pipes, this ‘plastic pipe pressure and burst testing equipment’ thing is an essential tool. It’s like a power tool for pipe testing, making sure they can withstand normal usage without failure. Alright, let’s delve into the five most common inquiries about this extremely critical testing equipment.

How does this plastic pipe pressure and burst tester thing actually work?

What are all the parts that make up this plastic pipe pressure and burst tester?

What usually causes plastic pipes to burst?

How do you make sure your test results are super accurate?

What’s the future looking like for testing these plastic pipes for pressure and burst?

How does this plastic pipe pressure and burst tester thing actually work?

Visualize this: the tester resembles a protagonist wearing a white coat, operating a sophisticated device to subject to pressure to plastic pipings. The process begins gradually, incrementally increasing the pressure until the hoselineline either withstands or collapses.

The entire procedure reveals the maximum pressure capacity of the hoselineline, crucial for maintaining its functionality over an extended period. The main element in this setup is the pressure meter, it is used to inform us of the pressure exerted on the hoselineline. This meter acts as a reliable companion, alerting you when the pressure becomes too extreme.

What are all the parts that make up this plastic pipe pressure and burst tester?

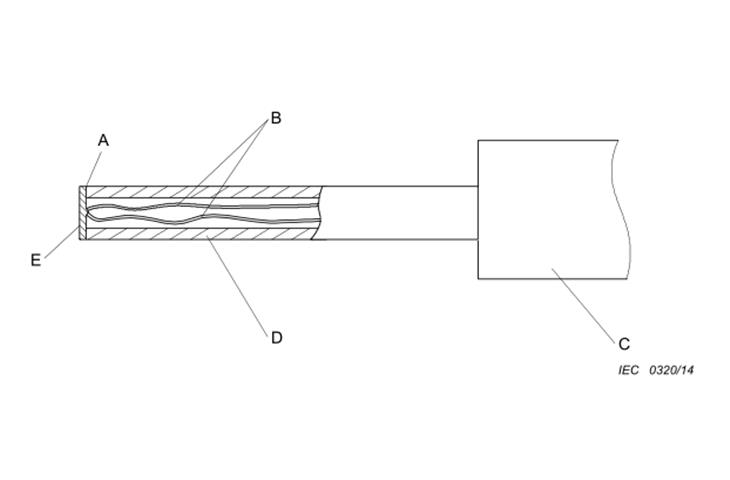

This powerful testing device comes with many main components. First off, there’s the pressure container, that’s where the pipe is placed.

Next, the pressure pump unit system unit system unit system unit, which provides the pressure, and the pressure indicator, our reliable companion. And lastly, the control mechanism, it’s what manages the entire testing process. All these components operate like a smoothly functioning machine to ensure the outcomes are accurate.

What usually causes plastic pipes to burst?

Exploding of plastic pipes is like a pile of cards. If a section is fragile, the whole thing can come down.

It’s usually because of substandard materials, improper installation, and stuff like heat and chemicals. Determining these factors is crucial for preventing pipeline failure and ensuring your pipes have a longer lifespan.

How do you make sure your test results are super accurate?

In pipe assessment, accuracy is huge. To ensure your results are perfectly accurate, you need to maintain your testing equipment rendszeresen kalibrálva.

It’s like giving your superhero a fresh pair of optical devices and a good workout. Calibration process makes sure the pressure gauge is working right and the compressor is putting out the right amount of pressure. And using superior materials for your pipes is just practical judgment.

What’s the future looking like for testing these plastic pipes for pressure and burst?

Plastic pipe assessment is constantly evolving. One big trend is adding intelligent technology to the mix.

Picture your superhero getting a state-of-the-art improvement, with detectors that can keep an eye on the stress and heat of the pipe like a pro. This will make it significantly simpler to detect issues before they even start.