Revolutionize Paper Bursting with Expert Insights

As a guy who’s been doing this Paper Pulping stuff for a while, I’ve seen just how neat this arrangement is. In the extremely busy paper world, this paper bursting machine has really attracted attention, making it a ease to turn . So, let’s jump into how this appliance works and check out some important terms.

Automated Paper Bursting Process

Automated Paper Bursting Process

This automatic Paper Pulping thing is like a contemporary engineering marvel. It’s arrangement better than the conventional arrangement of destroying paper manually, and it’s extremely precise and quick.

It all starts with paper being inserted into the machine and getting a soft yet firm grip. Then the machine uses really powerful air to shred it into small pieces. After that, it’s all collected and shipped to the pulp facility. This setup greatly reduces time and reduces the number of personnel required, making it popular among paper manufacturers.

High-Pressure Air System

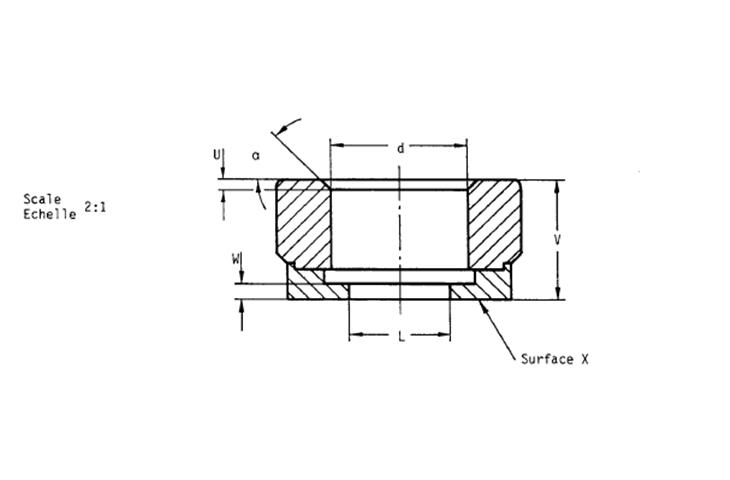

The real star of the paper bursting machine is its air system, which uses exceptionally strong air to bust the paper up.

It’s usually comprised of a compressor used to generate strong air, a pressure regulator, and pipes and valves to circulate the air. The air gets extremely compressed and then injected into the bursting area to break the paper apart. The effectiveness of the air system is extremely crucial for how well the whole machine runs, so it’s a extremely crucial part of this process.

Pulp Quality Control

The main job of paper bursting is to produce high-quality pulp. That pulp needs to be excellent because it affects how strong and long-lasting the paper is in the end.

To keep the pulp excellent, these machines have fancy monitoring systems that keep an eye on the procedure and adjust the pressure and additional adjustments. This way, the paper breaks optimally, making sure the pulp hits the maximum quality.

Environmental Considerations

With environmental stuff being super important these days, paper bursting machines have been getting better at causing less harm to the environment. These new machines are engineered for lower energy consumption and reduce waste.

For instance, they use the air again and have filters for dust trapping that comes out. These environmentally friendly features make the machine a favorable choice for paper manufacturers who concerned about the environment.

Conclusion

Working using this machine through the years, I’ve seen how significant it is a in the paper industry. It’s a important matter because because of its automatic, uses robust airflow, produces excellent pulp, and it does not pollute the environment. Staying up-to-date with latest advancements in pulp paper technology has assisted me improve in my role and has supported the company’s success. If you’re you want to go into more depth into the mechanism of how this machine operates, here are a few points to consider:

1.