Mastering Sheet Metal Body Panel Forming

Oh, producing car body panels from metal is super important in automotive manufacturing, and I deeply involved in it. It’s quite cool. It’s all about transforming those flat pieces of metal into attractive, curved shapes that compose a car’s body. So, this article delves into the detailed explanation of the process, discusses the challenges the challenges we encounter, and the techniques we employ to fix them.

What are the toughest parts about bending that metal into car bodies?

So, how do you make the metal better before you start bending it?

So, what are all these ways of bending that metal into shape?

How do you make bending metal more efficient and cut down on waste?

What are the toughest parts about bending that metal into car bodies?

The hardest part about forming sheet metal is getting it right every time, you know, making sure it’s good and doesn’t mess up. It’s all sorts of stuff, like the quality of the metal, how precise the molds are, and how well we control the bending process.

For example, using good quality materials helps, but you also need super precise molds and a really good process. According to some studies, if you get the molds just right, you can cut defects by a third!

So, how do you make the metal better before you start bending it?

You really gotta get the metal right before you bend it. It’s all about picking the right stuff, treating it right, and making sure it’s spot on.

I’ve found that using materials with high flexibility and toughness, like strong metal, can greatly enhance the shape production. And for example shot peening or the said phosphate layer ensures paint adherence and avoids rust. The Auto Materials Partnership says that superior surface finishes extends metal durability twice as long.

So, what are all these ways of bending that metal into shape?

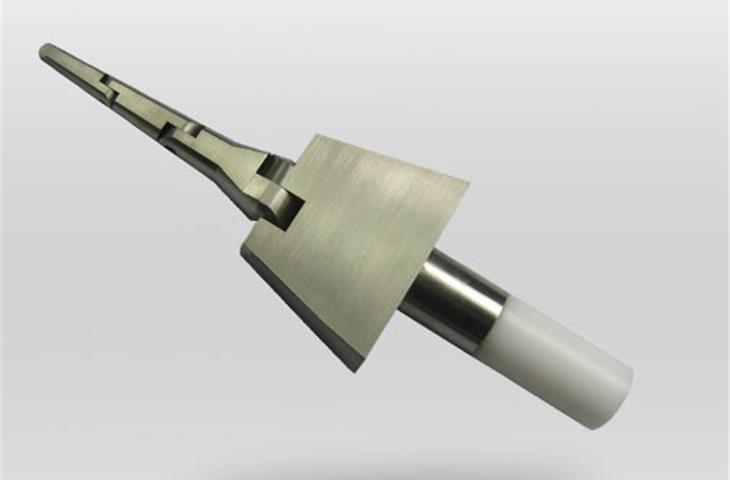

There are different ways to bend bent metal shape for car bodies, each with its own good points and downsides. Options like deep drawing, stretch forming, hydroforming, and roll forming are all in the mix.

I’ve done a lot with deep drawing – it’s great for making those deep, cup shapes. And stretch forming is perfect for those challenging forms with really constricted arcs. These types needs distinct machinery and technical know-how, and choosing the appropriate process for what you’re making. IJAMT has a lot of great stuff about these processes and what they’re applied in.

How do you make bending metal more efficient and cut down on waste?

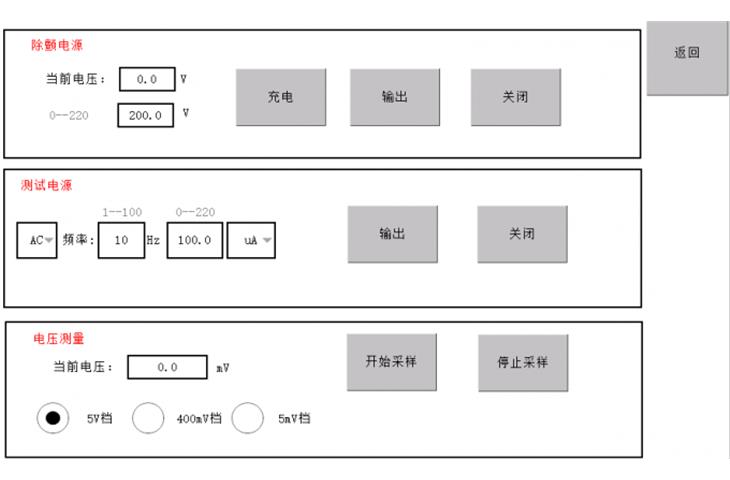

Improving forming operations is crucial for reducing waste and increasing efficiency. It essentially involves utilizing advanced software to determine how the metal will deform, improving the mold design, and maintaining control over the process.

I’ve witnessed how all these optimization techniques truly yield benefits. For instance, by employing finite element analysis, it functions as a crystal ball – you can forecast how much the metal will elongate, optimize the mold design, and prevent cracking or wrinkling. The Automotive Industry Action Group (AIAG) (AIAG) states that these techniques are extremely crucial for minimizing scrap and accelerating the entire process.