Mechanical Shock Test Machine: The Ultimate Price Guide

So, when we’re talking about ensuring materials are durable and enduring, this shock testing equipment is extremely crucial. This nifty machine can replicate what occurs during a hard impact. It assists individuals such as engineers determine how robust their materials are under various conditions.

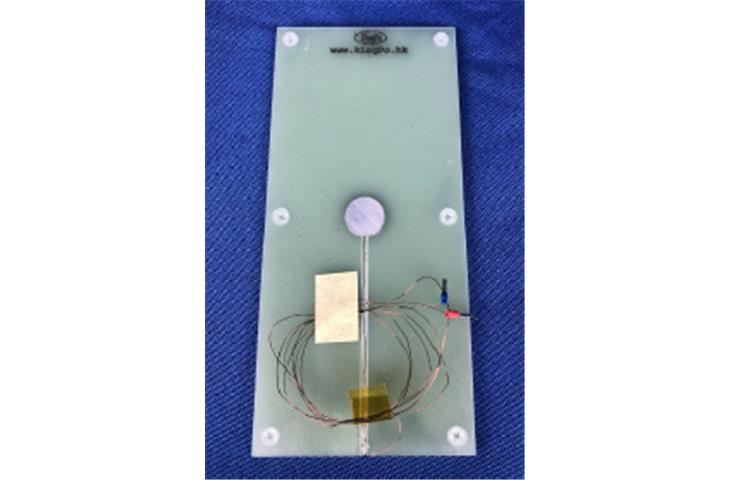

Impact Testing Machine

Impact Testing Devices are designed to subject materials to abrupt, high-intensity impacts. They are essential to industries like automotive, aerospace, and construction, where comprehending the material’s response to shock is vital.

You know, one cool aspect about performing this kind of shock testing is it can identify issues in materials that aren’t evident when they are merely being used in usual conditions. Take the aerospace industry, for instance. They often cope with a significant issue when materials in airplanes fail to sustain during a hard hit. Using a shock testing device, engineers can detect these issues early and resolve them to improve the material further.

Dynamic Testing Equipment

There’s this particular kind of shock testing machine called dynamic testing equipment. It’s like the shock testers’ younger brother, focused on how materials hold up upon being struck suddenly. This is extremely useful for observing how materials respond when they’re suddenly hit really hard, kind of like what happens in accidents.

A well-known test in this category is the Charpy impact test method. It’s all about the amount of energy a material absorbs when a rod with a notch gets hit hard. They frequently employ this test in car-making to determine the toughness of the components that go into cars. Therefore, utilizing this equipment assists automakers ensure their vehicles are not merely strong but also safe for drivers.

Material Testing Machine

These Testing Devices are pretty versatile. They help verify how products act under different circumstances. They can perform lots of experiments, like pulling forces, compressive forces, bend, and impact testing to see how products stand.

One widely used kind is the all-in-one testing machine. You can adjust it to perform different experiments based on the product you’re examining. So, if you’re testing a new polymers for electronic devices, you can use this machine to simulate how it would stand when it’s actually being used. That way, the manufacturers can make sure their stuff is secure and reliable.

Resilience Testing Equipment

Flexibility test machines are all about seeing how much a product can take without fractureing. They’re super important for stuff that needs to be secure, like car inflators and breakproof glass.

A type of test that they conduct involves stretching the material in order to determine its stretchability until it reaches the point of breaking So, with the help of this equipment assists engineers in ensuring ensures that their products will not merely withstand and is also able to cope with the actual forces that they will encounter

Based on what I have observed, selecting an appropriate shock testing equipment involves having a clear understanding of its intended purpose. Like, should you be in the aerospace field, then you may require an apparatus which can simulate highly rapid impacts along with extremely low or high temperatures.

However, if you work in the automotive sector, then you may require an apparatus designed to simulate a vehicular accident. So, take your time, figure out your specific requirements, conduct thorough research. You will eventually locate the ideal fit for your requirements.