Buy Top-Notch Dropping Ball Impact Testers

We need the dropping ball impact tester to ensure our products and materials are secure and durable. These devices simulate what occurs when when an object drops ontoto on a surface, providing engineers and creators valuable information.

At Our Company, we acknowledge the importance of employing dependable and superior testers to carry out precise impact tests. In this piece, we will investigate the importance of dropping ball impact testers and dive deep into the characteristics of highly ranked units.

Impact Resistance Testing

Testing how kinds of materials such as plastics, metals, and composites handle impacts is super important for creating and ensuring they’re good quality. Our team has been using these collision testers to see how materials hold up when we mimic everyday falls.

One of our recent projects involved testing the shock absorbency of a new series of strong plastic components. With the dropping ball tester, we could simulate a descend and observe how much energy absorbed by the material. The results helped our clients choose the right materials and make their designs better.

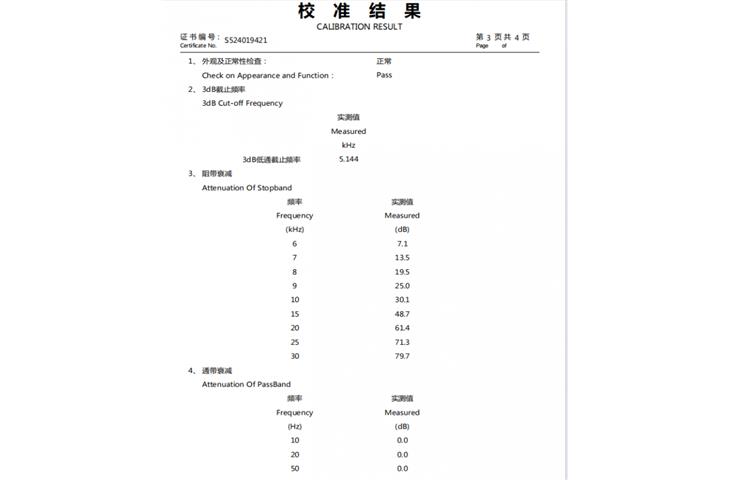

Accurate Test Results

The real plus of these collision testers is that they give us reliable and consistent outcomes every time. We’ve applied these testers to numerous projects, and they’ve always given us exact and consistent outcomes.

For example, we worked with a big automotive manufacturer and used the tester to check how safe a latest vehicle bumper design was. The test findings were super important for deciding if the bumper could withstand collisions without damaging the car. Our clients were really impressed with how accurate and reliable the test findings were, which helped them feel good about making decisions about their product.

Compliance and Standards

In a lot of industries, you’ve got to follow certain specifications to make sure your products are safe and high-quality. Our vibration test devices are built to meet those specifications—like ISO 179, ISO 2243, and ASTM E832.

We’ve worked on projects that needed to follow those specifications, and our testers have been great at helping us meet those requirements. We worked on a project where we had to test some new construction materials to make sure they met European specifications. Our testers helped our clients achieve compliance and improve their products’ safety and performance.

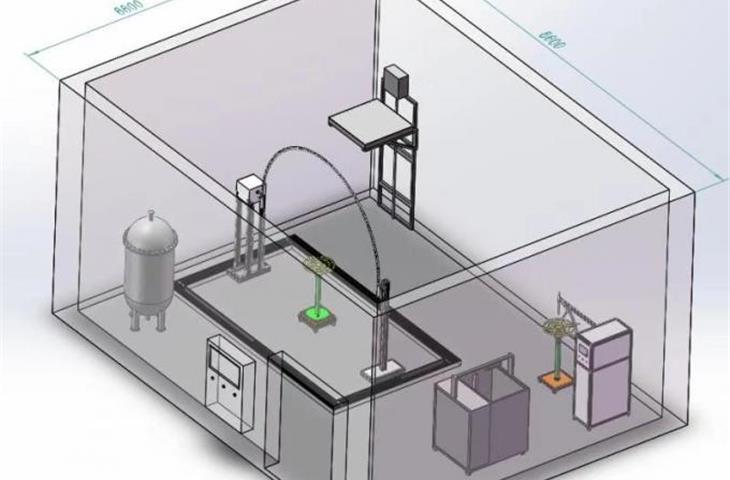

Customization and Versatility

At Our organization, We have a variety of drop testers that we can tweak to tailor to each client’s specific needs. Our staff has a considerable expertise making The drop testers, so they are very versatile and can conduct varying kinds of tests.

We undertook a exciting project where we custom-developed a tester for a customer. They required for testing purposes an especially distinctive material. We collaborated extensively alongside The customer to guarantee the device perfectly suited for their needs. It functioned well and The customer was exceedingly satisfied.