Why Abrasion and Wear Testing Machines Are Essential

So, we’re talking about components that withstand the stress. Sturdiness is a big deal, you know. We need them not to deteriorate rapidly. And that’s where these Excellently Designed abrasion and wear testing machines come into the picture.

1. Importance of Abrasion and Wear Testing in Material Selection

2. Types of Abrasion and Wear Testing Machines

3. Benefits of Using Abrasion and Wear Testing Machines in Manufacturing

4. Challenges in Conducting Abrasion and Wear Tests

5. The Role of Abrasion and Wear Testing Machines in Sustainable Development

So, these instruments are super essential to examine how well various substances withstand all sorts of circumstances. We’re going to get into numerous critical features about these machines. I’ll be sharing my insights and experiences, both from professionals and individuals just like you.

1. Importance of Abrasion and Wear Testing in Material Selection

Finding just the right substance can be a challenge sometimes. These small machines are a tremendous assistance for technicians and researchers to determine which substance is suitable for a certain task.

Some research indicates that if a substance goes through lots of abuse testing, it usually does significantly improved in the . They ensure the substance we use can deal with whatever what it is designed for in the , you know?

2. Types of Abrasion and Wear Testing Machines

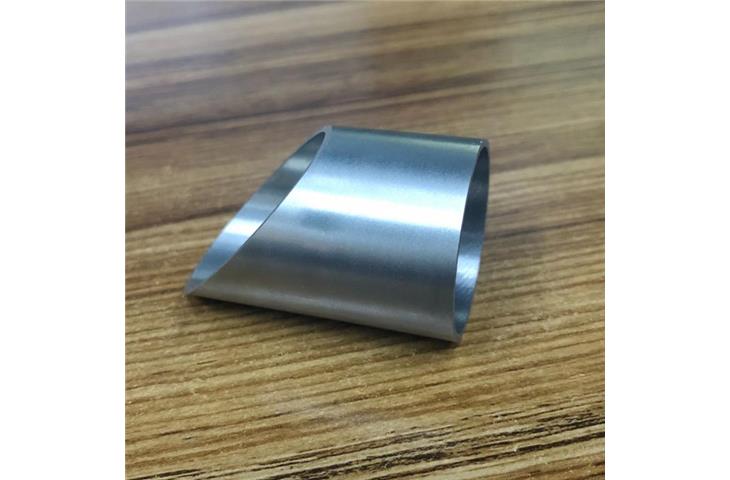

There are different kinds of abrasion and wear testing machines accessible, which are intended to mimic different wear scenarios. The most common ones are the pin-and-disc tester, ball-and-disc tester, and the linear abrasion tester.

Each of these machines has its particular methods and advantages. For instance, the pin-and-disc tester is excellent for assessing the wear resistance of coatings, while the ball-and-disc tester is Appropriate for assessing the wear resistance of lubricants. Upon mastering all these various tools, you can select the most suitable one for your testing job.

3. Benefits of Using Abrasion and Wear Testing Machines in Manufacturing

These testing equipment are pretty much a no-brainer for manufacturers; they get numerous benefits from them. They identify problems with materials and components before the manufacturing process is complete, so it’s more manageable to address.

One report from those testing individuals, called ASTM, said they can benefit companies considerable money in the long run; up to 20% especially. If companies invest some money into these machines, they can greatly reduce on downtime and improve the quality of what they make.

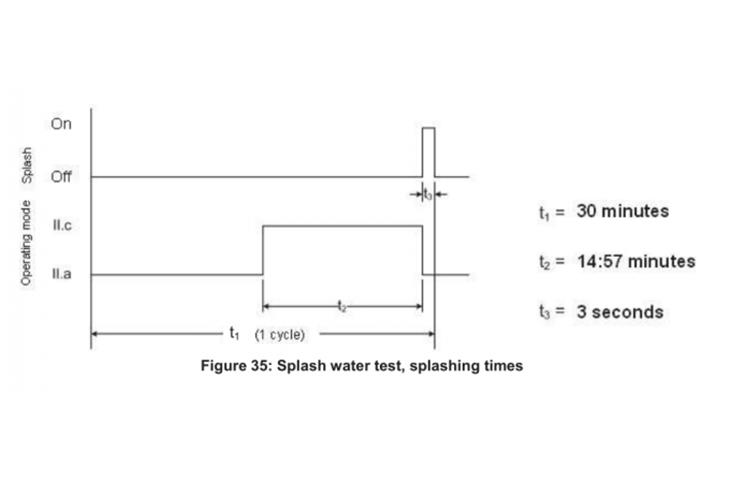

4. Challenges in Conducting Abrasion and Wear Tests

Now, doing these abrasion and wear tests has its own challenges, like making sure you choose the right settings and trying to interpret of the results. But to really get past them, you gotta follow the industrial standards.

Now, a study printed in the International Journal of Fatigue made a argument for conducting these experiments correctly resulting in precise outcomes. And when you understand the complexities of these tests, you can confidence in your results being perfectly applicable, no doubt.

5. The Role of Abrasion and Wear Testing Machines in Sustainable Development

In the current era, sustainable practices are of utmost importance. These friction and wear testing equipment really enable us to create improved, stronger materials that’s also environmentally friendly.

By helping to reduce the need for frequent replacements, they produce less waste and preserve what we have as well. The report by UNEP shows the significant aspect about materials and products dealing with these ecological issues, no doubt. By using these testing gadgets, we can each of us contribute in a more sustainable planet. Right?