Delving into Withdrawal Forces for Connectors: Ensuring Secure Connections

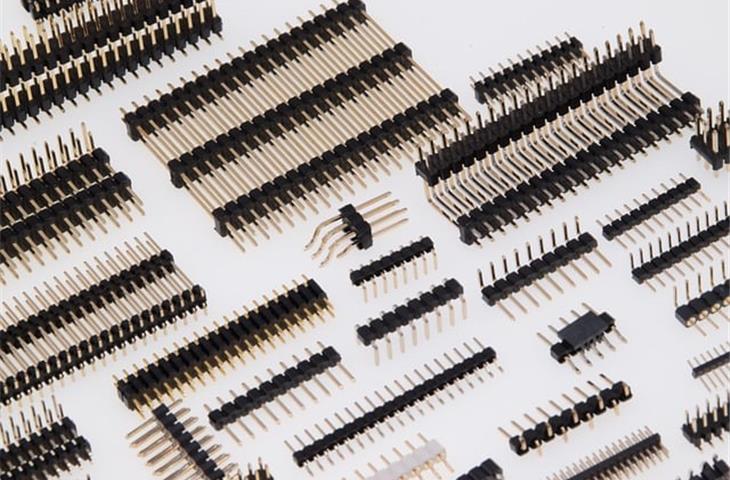

Connectors play a pivotal role in forming trustworthy and long-lasting connections in the realm of electric and mechanical systems.The withdrawal force for connectors is a crucial element that guarantees the durability and reliability of these connections.For engineers, designers, and technicians to ensure optimal performance and safety in various uses, understanding the withdrawal forces for connectors is essential.

This article will delve into the intricacies of withdrawal forces for connectors, emphasizing their importance and examining four essential criteria that need to be considered. These requirements are to achieve secure and solid connections.For various reasons, withdrawal forces for connectors are crucial:

Connectors must possess a adequate withdrawal force to avoid accidental separations.The force should be high enough to withstand normal manipulation and atmospheric conditions without causing unplanned disconnection.Achieving this equilibrium requires deliberate thought of the connector’s design parameters and the use needs.

To guarantee a reliable connection, the withdrawal force of a connector should be compatible to the mateable components.This compatibility is essential to prevent excessive force during insertion and extraction operations, which can lead to deterioration on the connector and its mating interface.multiple environmental influences, such as shake, temperature fluctuations, and stress, are often exposed to connectors.

The withdrawal force should be robust enough to withstand these factors without compromising the connection’s stability.To make the connector hard to disconnect, especially in confined or cramped areas, the withdrawal force should not be very high.Hence, it is crucial to achieve a balance between sufficient withdrawal force and ease of use.

Several design and material considerations must be taken into account to achieve optimal withdrawal force for connectors:To achieve the required withdrawal force, choosing the right material for the connector’s housing and contacts is crucial.Brass, stainless steel, and specific polymers offer good strength and durability, making them suitable for various applications.

While maintaining convenience, the layout of the connector should incorporate characteristics that enhance pulling force.To ensure that the pulling force meets the usage specifications, testing and validation are critical.In some cases, the specific requirements of an application may not be met by routine connectors.

Personalizing the connector design or developing a new strategy may be necessary to achieve the desired pulling force.In conclusion, to ensure safeguarded connections, pulling forces for connectors are vital factor.Through understanding the importance of pulling forces and by considering the four key requirements outlined in this article, engineers, designers, and technicians can choose and develop connectors that meet their application’s needs.

By focusing on component choice, design characteristics, testing, and validation, as well as on application-specific strategys, it is possible to achieve optimal pulling forces for connectors. This contributes to the total efficacy and safety of electromechanical systems.